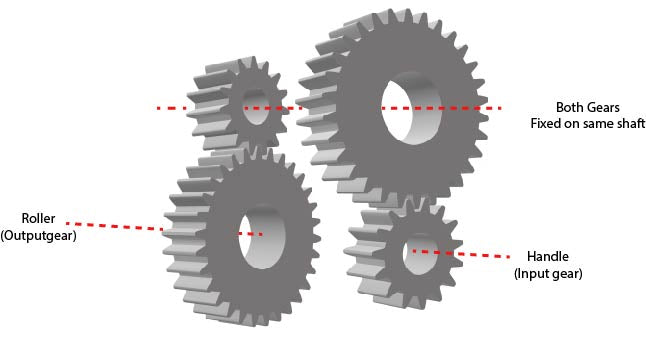

The Pepetools 4:1 Gearbox

Illustrations by Dave Wilson of the 4:1 gearbox

Note the input on the right and output on the left.

The two top gear are fixed together on a shaft.

The Pepetools range of rolling mills feature their custom designed 4:1 gearbox. But what exactly does it do? and why is this such an essential addition to your rolling mill? Here we explain the clever science behind it and the many advantages to the jeweler and metal worker.

A gearbox can offer many features. It can be used to increase or reduce the speed, the direction and even the force. By cleverly combining various properties it is possible to greatly reduce the user effort required.

“Give me a lever long enough and a fulcrum on which to place it, and I shall move the world.”

Archimedes. Greek Mathematician c. 287 – c. 212 BC

You don’t have to be an ancient Greek mathematician to know that Archimedes was right. If you’ve ever tried to use a pry bar to move a heavy object, you'll quickly understand that the longer the pry bar the more force you can exert. You may also have noticed that as the pivot point moves closer to the tip, the force is increased.

The Pepetools gearbox may appear tiny, but it uses the exact same principles. Instead of levers and pivots is uses precision engineered gears, and by varying their diameters and ratios the forces can be manipulated and controlled to benefit the user.

So why do why don’t Pepetools just make a 1,000: 1 gearbox?

You might think that if a gearbox can amplify your strength, then why not make one that can amplify it thousandfold. In theory, a 1,000: 1 gearbox would increase your force, but the result would be a lot more movement required. You would have to wind the handle 1,000 times to produce a single revolution of the rollers. The point is,there is always a trade-off. You must put energy in in order to get energy out. The Ancient mathematicians called this “conservation of energy”.

“Energy can never be created nor destroyed; it can only be transformed.”

So, what does this mean for a rolling mill? In short, it means you don’t get anything for free. Squeezing a piece of metal into foil requires an immense amount of force. There is no way anyone could squeeze solid metal with their bare hands. However, we “are” capable of moving small loads repeatedly. This is where the gearbox comes in, converting movement into power.

Have you ever tried cycling up a steep hill? In the lowest gear, you have to pedal very fast in order to move very slowly uphill. The gears on the bicycle are converting the increased movement of the fast pedalling into the increased force required to move the bicycle (and yourself) up the hill. The gears are converting movement into force. Once back on the level you can change up gears and convert a lesser movement (but more force) into more speed.

The Pepetools gearbox, uses the same principle, a small 4X increase in movement creates enough force to bend and form tough metals with ease.

With a simpler rolling mill, you may see the handle connected directly to the bottom roller. In this scenario, a single turn of the handle produces one turn of the roller. There is no mechanical advantage other than that provided by the leverage of the handle. Often these mills can be difficult to control as the metal moves quickly through the rollers. It can also be hard to work with heavy gauge material, requiring a lot of force to be applied to the handle.

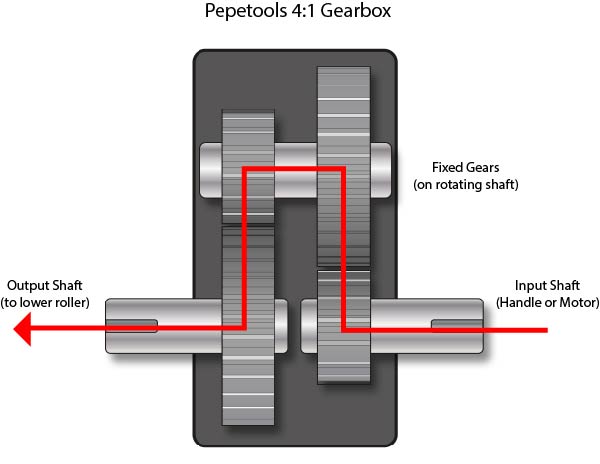

showing how the power is transferred Through the gearbox.

What Pepetools have done is to sever that link between the handle and the roller. As you can see in the illustration above the power from the handle turns the small input gear, this turns a larger gear mounted on the shaft. On the other end of the shaft is another small gear that turns a large output gear on the end of the roller. By transmitting the power through this second fixed shaft, it allows Pepetools to utilise the principles of the different gears to generate increased power, within a very small gearbox.

Illustration By Dave Wilson

showing the relative rotation of each gear

In a simplified version above. The input gear (A) has just 15 teeth, and it turns the larger top gear (B) which has a greater diameter and 30 teeth. Just as a pry bar has a long handle and a short pivot point, the combination of a small gear driving a larger gear gives increased power by converting motion into torque. As the handle and the input gear rotate once (15 teeth) the larger gear (B) will only rotate half a turn. Hence, we have halved the movement but converted it to increased torque.

As the upper two gears, B and C are fixed together on the shaft, they both rotate by the same amount, Hence C also rotates ½ turn. Now just 7 ½ teeth for every rotation of the handle.

This second small gear drives the second 30 tooth larger gear D which is fixed to the end of the roller. Again, the power is amplified by the act of the small gear driving a larger one. Each half turn of C. only turns the large roller ¼ turn. So again, the movement is reduced, and the power increased. The final roller only moves ¼ turn, for every turn of the handle. Or to put it another way, four turns of the handle give one turn of the roller, hence the expression 4:1 four in - one out. By the use of the two small gears driving two larger gears, the rotation is halved and then halved again, but the power is greatly amplified. An additional advantage of this design is that the roller rotates in the same direction as handle is turned. Which makes for logical operation.

Getting a grip. Of course, you have to put in the movement and how you do this is equally important. Pepetools has created an extra-long and extra tough handle that has been forged (not cast) for almost indestructible strength. The long length gives maximum leverage, whilst still allowing the tool to be used with a typical workbench location. Finally, they have machined a solid beechwood handle, allowing a secure and comfortable grip, which gives a high level of feedback to the user allowing both comfort and control.

The Pepetools 4:1 gearbox is machined to precise tolerances, using the best materials and processes: hardened steel gears, treated and finished, combined with brass bushings, and solid aluminium housing, all combine to create a tough gearbox capable of delivering the torque and power you require. The result is a smooth comfortable mill which is very easy to control. The handle requires very little force, but the mill has the extreme power to bend and shape even the toughest and thickest of materials with ease.

All Illustrations hand drawn by Dave Wilson

Using Adobe Illustrator and Adobe Photoshop

All images Copyright Pepetools.

by Dave Wilson

www.celticdreams.co.uk

© 2020 Pepetools.

www.pepetools.com