$438.46 $515.83

About Foredom Classic Jewelers Kit with H.30 Handpiece

The Foredom flex shaft (or pendant drill) is an essential part of every jeweler's workbench. It features a powerful motor that is suspended above the workbench, either on a hook or on the Optional Foredom stand, (Not included). It hangs like a pendant – hence the name. Attached to the motor is a long flexible shaft (again hence the name). At the end of the flexible shaft is the handpiece. This means the motor is not held in the hand which makes the handpiece small and maneuverable. The motor is controlled by a sensitive foot pedal allowing precise control of the bur at your fingertips.

The Foredom Flex shafts offer the ultimate in USA quality, with solid metal housings, smooth, vibration-free movement, and high torque, high power motors. Delivering precision and power right to your fingertips. An assortment of interchangeable handpieces are available. So, whatever the task Foredom has a handpiece and accessory for you.

The K2230 is a complete kit, ready to go out of the box, simply hang up, plug in, and go. It comes complete with the Foredom SR motor, featuring 1/6 HP, with a reverse feature operating at up to 18,000 rpm. With solid metal housing and ball bearings, it's robust, smooth, and powerful. It takes all the work out of sanding, grinding, and polishing. Note that both 220v and 110v versions are available. Control is via the included Foredom Foot pedal, made from tough abs, it offers smooth consistent control through the entire speed range.

Attached to the 39” flex shaft is the H30 handpiece. Without a doubt the most versatile. Machined from solid aluminum, it features a small “Jacobs Chuck” 3 jaw chuck and a chuck key. Which can accommodate accessories of different sized shanks, this makes it ideal if you are upgrading from a handheld rotary tool with nonstandard accessories. The flex shaft incorporates a key tip design for rapid changing of handpieces, which just snap on and off.

Designed for the jeweler, this kit contains an assortment of accessories to get you started, including drilling sanding, and polishing accessories. For example…

Grinding stones, for shaping and smoothing metals, rubber wheels, and points for polishing metals. A Selection of nylon and wire brushes for cleaning and polishing small items. Sanding drums, for material removal on metal and wood. cotton polishing mop for final polishing on precious metals, with the polishing compound. There is also a range of burs for engraving and cutting. The kit allows you to try out different techniques whilst you get used to your flex shaft. 1,000s more accessories are available for every possible material and task.

The kit even comes with an accessory stand with space for lots more accessories. There is also a tube of grease for occasional maintenance of the flex shaft. The whole kit comes attractively packages in a full color box, making an ideal gift for any jewelry, hobbyist, or crafter.

Note this kit does not include the stand. It is designed for attaching to a hook or bracket on the wall. For an immediate and movable option, see the optional Foredom Stand.

Get to work right out of the box with this inclusive Foredom® K.2230 system with plastic foot pedal—ideal for a variety of bench tasks. The powerful SR motor is designed for improved performance and has the extra power needed for continuous production use in all jewelry manufacturing operations. The kit includes an H.30® chuck-style handpiece that accommodates a wider range of tool shank sizes for a wider range of applications. Control speed easily and instantly with the FCT plastic-housed foot-operated speed control.

- Powerful, 1/6hp ball bearing 18,000rpm SR motor has a switch for forward or reverse direction. Maximum speed is 18,000rpm.

- Foredom H.30 chuck-style handpiece; opens from 0" to 5/32" (0–4mm), so you can get more done with a wide variety of shank sizes.

- Foredom® plastic-housed, FCT-1 slip-resistant, heavy-duty, solid-state electronic foot control that allows control from low to full speed

- The flexible shaft with quick-detach feature accepts any Foredom handpiece except H.30H, H.44HT and H.28H.

- Excellent quality Foredom® H.30® handpiece with adjustable key-type chuck that fits shanks from 0"–5/32" (0–4mm).

- CK-0 chuck key in molded plastic for changing accessories

- 43-piece accessory kit, which includes rotating bur and tool holder, mounted points, wire and bristle brushes, sanding drums, 3M radial bristle discs, assorted buffs, polishing wheels, compound, mandrels and flex shaft grease.

- Limited two-year warranty on motor and foot control; 90-day warranty on handpiece.

Kit set includes:

- M.SR motor.

- H.30 chuck-style handpiece.

- FCT plastic-housed foot-operated speed control.

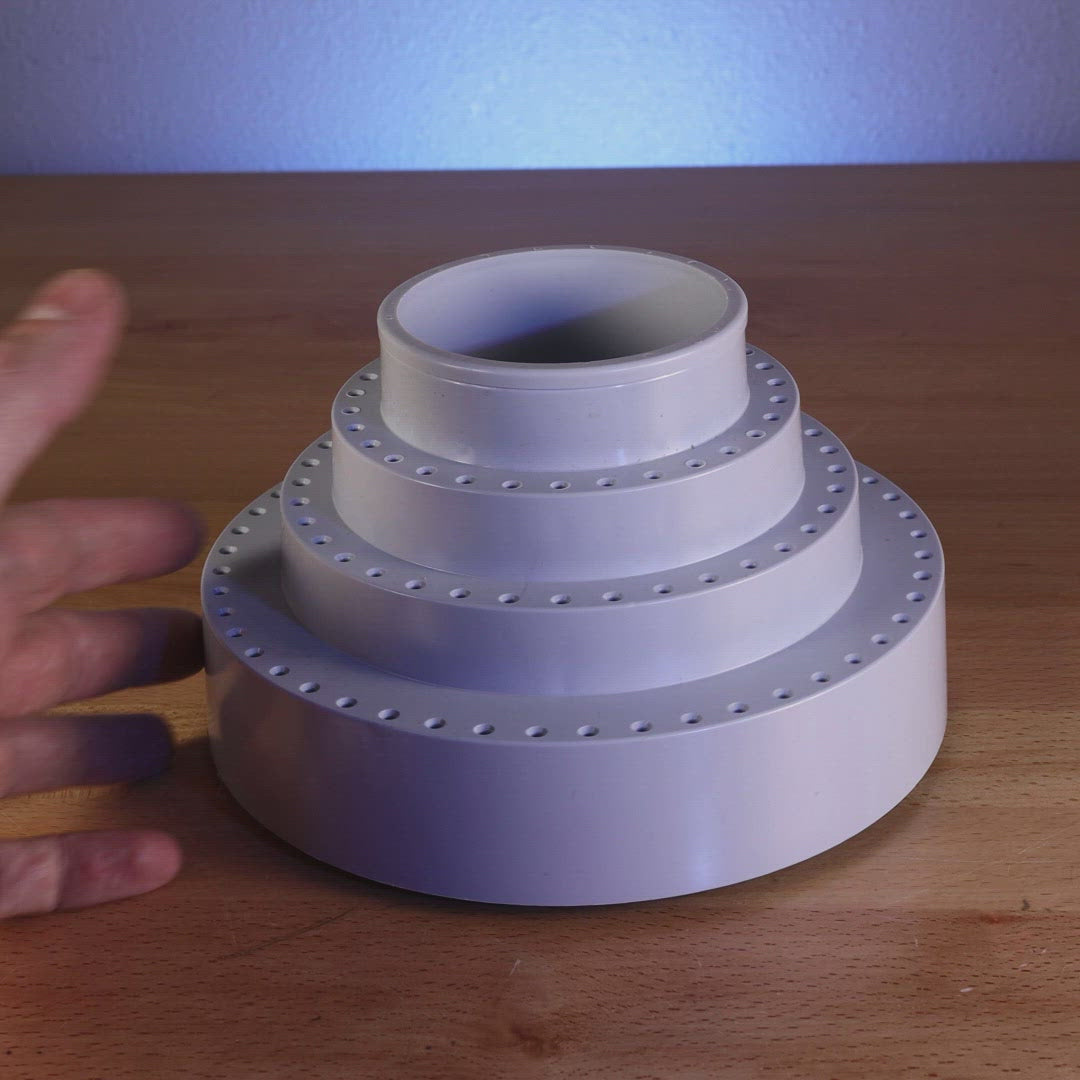

- AK-11 43-piece accessory kit, which contains: a rotating bur and tool holder, mounted points, wire and bristle brushes, sanding drums, 3M radial bristle discs, assorted buffs, polishing wheels, compound, mandrels and flex shaft grease.

UPC 098666022306

TIPS & TRICKS

1. Proper Shaft and Sheath Alignment

• Check that the inner shaft extends 3/4″ (19mm) past the sheath before attaching the handpiece. This alignment prevents friction, overheating, and undue wear on components.

• If you notice vibration or excess heat at the handpiece or motor, re-check your shaft-to-sheath adjustment.

2. Use the Right Motor Rotation

• The SR motor features a Forward/Off/Reverse rocker switch. Typically, “Forward” (clockwise under load) is used with burs, drills, or cutters. “Reverse” can be helpful for left-handed use, clearing jammed drill bits, or extending the life of certain abrasives.

• Never change from Forward to Reverse while the motor is still turning, to avoid damaging the internal components.

3. Employ Smooth Bends

• Keep your shaft’s bend radius to about 4″ (10cm) or more. Tighter bends cause unnecessary wear on both the shaft and sheath. If possible, arrange your workspace so that the shaft extends in a gentle arc.

4. Grease the Foredom Flexshaft

• Lightly grease the inner shaft about every 40 hours of use and thoroughly clean it every 200 hours. Use a high-quality white grease or Foredom’s own shaft grease. Over-greasing can result in excess grease seeping into the handpiece.

• Hang the motor over a trash can and run at low or medium speed for a few minutes after re-greasing to allow excess grease to spin off before re-attaching the handpiece.

5. Match the Right Handpiece and Accessories

• Only use accessories rated for at least 18,000 RPM (the maximum speed of the SR).

• Ensure the mandrel or bur shank is securely seated in the handpiece’s chuck or collet.

6. Keep the Motor Clean

• If you operate in high-dust environments, clean out the motor’s air vents regularly by removing the brushes and blowing compressed air through the motor housing.

• Replace motor brushes (found on each side of the housing) if they have worn to about 1/4″ (6mm) in length.

7. Use a Secure Hanger

• Hang the SR motor about 30″–40″ (76–100cm) above the work surface. Always use a safety clip or closed hook so the motor doesn’t jump off at startup or from vibrations.

8. Start Slow, Then Speed Up

• Whether using a foot pedal or a dial control, begin at a lower RPM and gradually increase speed. This helps you find the sweet spot for each bur or accessory without overloading the motor or damaging the workpiece.

SHORT FAQ

Q: How often should I grease the flexible shaft?

A: Lightly grease the shaft about every 40 hours of use, and do a thorough cleaning plus re-greasing around every 200 hours.

Q: The motor is getting very hot. Is this normal?

A: The SR motor can run quite warm (up to roughly 100°F above ambient). This is expected. Ensure you allow proper air circulation around the motor and keep dust from clogging the air vents.

Q: Why is my motor vibrating heavily?

A: Check shaft alignment (3/4″ extension past the sheath), examine for tight bends, and verify that everything is lubricated. Also confirm that the handpiece is firmly attached and balanced accessories are used.

Q: Can I change the direction from Forward to Reverse to clear jammed burs?

A: Yes, but always switch the rocker to the “Off” position first. Changing rotation while the motor is running can damage the shaft or motor.

Q: How do I know when to replace the motor brushes?

A: Replace them when they are worn down to about 1/4″ (6mm). They are approximately 3/4″ (19mm) when new.

Following these simple guidelines helps keep your Foredom SR running smoothly, maximizing both efficiency and the life span of the tool.

Recently Viewed

Helping you to

Keep crafting

#PEPETOOLS

Show us what you're creating